Ongoing Preservation of Tyrone

I purchased Tyrone in the summer of 2021. A year prior I was living in Tacoma, Washington working as an engineer and living on my smaller Bill Garden schooner Blue Starr. I had experience in leaving a well-paid engineering job before when I purchased Blue Starr and moved across the country from Michigan. After somewhat reviving Blue Starr, building two new masts for her and crossing into the realm of keeping up with the needs of such a boat, I was again burnt out with the frustrations of a corporate desk job and longed for more. When Tyrone came up for sale I jumped at the opportunity. I knew that offering overnight sail training trips on a slightly larger schooner was exactly what I wanted and maybe needed. Having had a family background in my teenage years with a large schooner running a charter business and some wooden boat experience, I decided to take the chance on Tyrone.

I flew out to Boston in February of 2021. Drove to Cape Cod and upon seeing the boat I immediately fell in love. From her graceful lines that hinted at Gloucester Fishing schooner and her relatively heavy construction I saw a lot of potential. I insisted on staying aboard for the two nights I would be there despite there being a fair bit of melting snow piled on the uncovered deck. The stay was very wet, cold and quite telling on the condition of Tyrone. In fact, there was not a dry spot on the boat save the galley table that folds down. It was a rather good thing I brought some serious camping gear. In addition to the very leaky deck it was clear the horn timber would need to be replaced with some urgency and the bulwark stanchions were completing their transformation to soil allowing for an alarming amount of water ingress. Those were the obvious issues.

In spite of the clearly difficult path ahead I decided to move forward with the purchase. Things went into motion quickly leaving my job, putting Blue Starr up for sale and eventually driving out with Otto, my truck and small trailer packed to meet Tyrone in Gloucester at the end of August 2021. I met the boat at Rose’s in Gloucester where I’d haul her, have her surveyed, do some maintenance and finalize the sale…

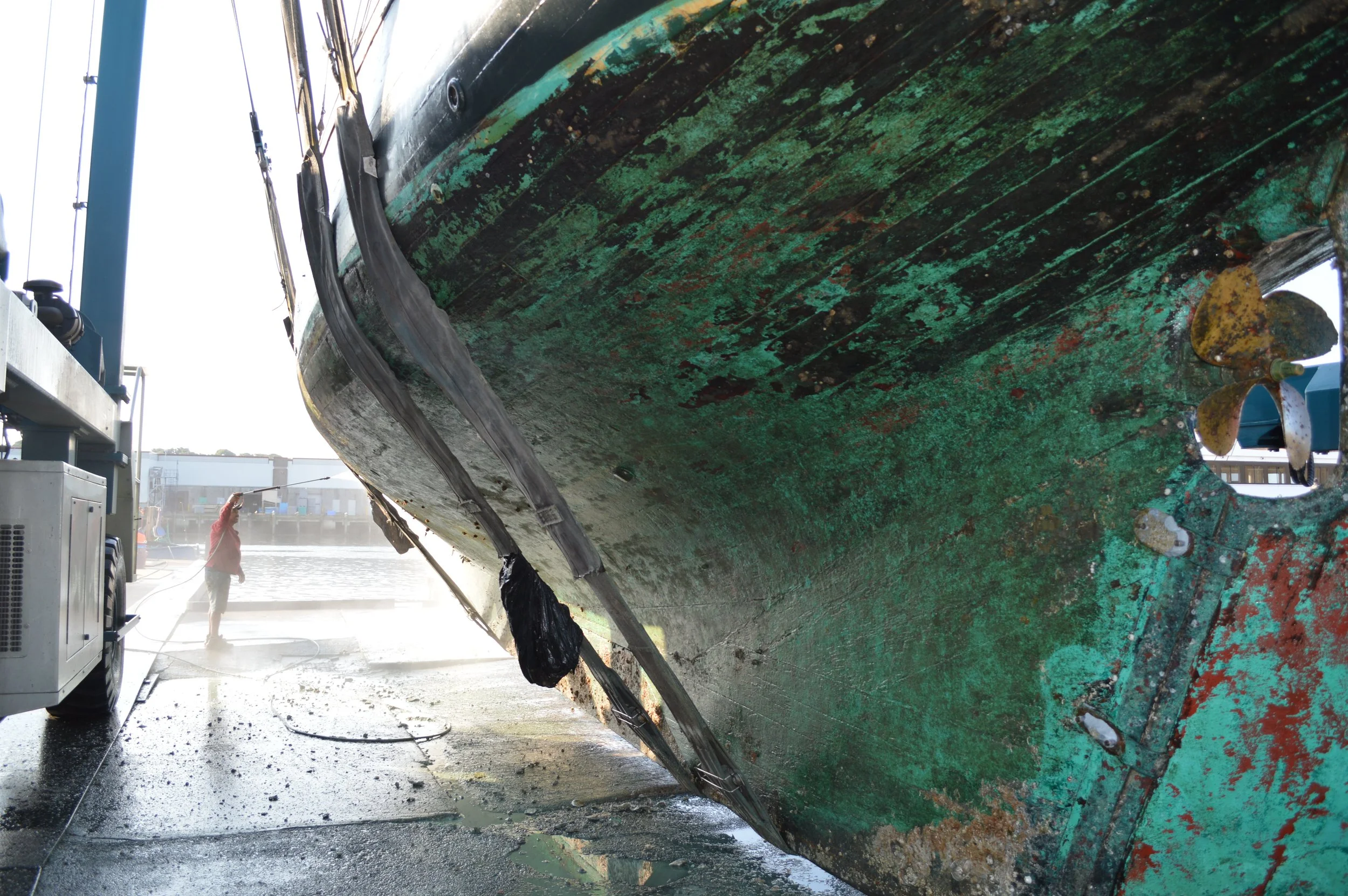

After hauling the boat at Roses it became alarmingly clear that I was in for more than routine maintenance. Two planks on the aft quarters were doing a good job of sinking the boat which at the time had minimal in the way of functional bilge pumps. The 4 blade propeller was also nearly dust from electrolosys. There was also an ant infestation in the planks at the galley which I found poking around the topsides. Somewhat fortunately, a gentleman introduced himself quite literally as I was standing there looking at the boat having just been hauled and completely overwhelmed. Brian thankfully helped me through the very grueling next three weeks in sanding and painting the bottom, replacing planks and generally getting the boat ready to go back in the water and be taken up to Maine.

After launch in Gloucester we decided to stick around a few weeks to take part in the Gloucester Schooner festival. Though she was far from the condition I would wish to put on showcase, we did end up taking second place in the race for our class and much more importantly, Carolyn by chance crewed for the race and that is how we met though we would go our separate ways for a year. After the festivities Brian, Otto and I waited out a hurricane in Gloucester and then shoved off for Maine.

Once in Maine the frantic search for winter dock space, covering the boat and making a plan for work started. It was becoming ever more apparent to me that in order to run the boat safely the horn timber needed to be replaced as soon as possible. Having run into many dead ends dock space wise and shipwright/boatyard wise I finally had some luck (albeit absurdly expensive) finding a place in East Boothbay to keep the boat for the winter. I hastily pulled the masts and bow sprit, moved the boat and got a makeshift winter cover put up that I thought would be sufficient. I got in touch with a local shipwright and made plans to replace the horn timber in the spring. Through the winter I repainted the interior of the boat, demoed and prepped for the horn timber project, built new spreaders, replaced the worst offending bulwark stanchions on the starboard side, reefed and re caulked a number of deck seams and started to demo a corner of the cabin house that was very soft as I inteded to recover the cabin top…

Living on the boat through that winter was particularly strenuous for Otto and I. In the fall prior I replaced the diesel heater that wasn’t setup well with a coal pot belly stove. Between the electric space heaters and the coal stove we managed to stay warm mostly. Lack of water at the dock is a pain to be sure once the onboard tanks ran out. The painting of the interior made comfort quite difficult. Things got quite a bit more trying in February after two Nor’easters managed to completely destroy the winter cover. Work continued from then on covering the boat with what canvas covers I had and working outside in good weather. The big project at this point was replacing the starboard bullwork stanchions. This required removal of the cap rail, bulwark plank and then the stanchions. They were replaced with locust stanchions and a new bulwark plank and mahogany cap rail.

The boat has a pretty neat shipmate propane stove and oven that is likely from the 50s or so. When I bought the boat the door on the oven was broken with little hope of fixing it as it was cast aluminum. Through the winter I kept an eye out for replacement doors and finally found one down in Connecticut that I could salvage the door from as a replacement. So I took the 4+ hour drive to go get it and fixed the oven door. I also picked up a beautiful dinghy on that trip which we intend to rehab this winter (2022) and get up and running for next summer.

The plan for the horn timber project was to haulout in Portland at the end of April and get to work. In the spring after the cover blew off it was also apparent that the stem would need repair. The rot was most significant where the gammon iron was through bolted (not shown in photos) which is a pretty scary thought for the rig.

Aside from the projects on the boat, it was also necessary to get the masts in order and I had decided to replace all the running rigging. It was a mad rush in a short week to get the masts sorted, rerigged and stepped prior to heading for Portland. Below shows some new leather on shroud eyes, a decent sized dutchman on the main and some of the old line which was replaced. It was quite inspiring to get the masts restepped even though it involved some drama with a storm that came in that day.

I motored Tyrone down to Portland by myself on April 24, 2022. The trip down was relatively uneventful except for the alarming amount of water collecting below my feet seeping in around and through the horn timber. It reminded me that I was making the right call completing this project as soon as possible. I hauled the boat at the end of the week at Portland Yacht Services and immediately got to work prior to the shipwright on the horn timber project starting. I demoed planks around the horn timber and setup staging.

Horn Timber Replacement and Stem Repair - Spring 2022

To remove the old horn timber it was necessary to remove the rudder, shaft, shaft tube, planks, frames and floors around the old timber. To drop the rudder we dug a big hole underneath. The shaft tube was a lead pipe which was collapsed first and pulled out.

The old horn timber and frames were quite shot. Floors already removed here.

After two weeks of demo and prep the old horn timber or what was left of it finally came out.

A beautiful piece of white oak 12”x12”x12’ came to shape the new horn timber along with white oak for new frames and floors. The new timber was shaped and went in first then frames and floors started to follow being patterned from the old and cut.

With the new horn timber in, rabbet cut, frames and floors installed planks started to go on. The planks started as 8/4 sipo and were quite tricky with all the shape around the horn timber.

While the horn timber project was being planked up much work was going on elsewhere. The cabin top/engine room hatch was being reconstructed (the shipwrights let me do this one myself and I think it turned out ok) and canvas going on and the topsides were being repaired (especially where the ants got to the shear plank on the port side) and prepped for paint. The cabin top was repaired with new mahogany sides and teak beams/carlins then covered with splined pine planks. The canvas went on over a bed of gesso and was painted with ezpoxy paint.

One day I was feeling a little frustrated with the lack of progress on the stem. Much to the shock of the shipwrights, while they were taking their lunch, I took a chainsaw to the rotten stem and kicked the project off. We removed much of the planks down to the water line on the port side and cut a decent scarf in the existing stem where it was still intact. A new piece of stem was shaped out of white oak and bolted to the existing stem from the waterline up. Carolyn shifted from other boats at this point to work on Tyrone and she was responsible for replanking the port bow, installing new bulwark stanchions, new knightheads and the cap rail. A new beak was laminated out of pine and bolted on as well. Unfortunately, when I dtook the old beak down Tyrone the figurehead took a spill so we hope to rehab him this winter and get him re mounted looking even better than before.

The next big task for the horn timber project was to bore out the timber for the shaft and rudder logs. This was nerve wracking. A new bronze shaft tube was purchased from RE Thomas in Maine with a new cutlas bearing housing and the original stuffing box housing used. The original rudder log bronze tube was reused. After the boring was done the hardware was installed and the new shaft from Accutech along with the beautiful new feathering prop was installed. The refurbished and new Aquadrive was also reinstalled.

New copper on the rudder shaft timber that was re drifted to the deadwood and getting ready for the rudder to be remounted. Had to dig out the hole again with all the stuff we dropped into it on accident. The rudder gudgeons are held in place by bronze rivets going through the timber and the deadwood which were also a very tedious task to install and peen.

Things were starting to wrap up. Shipping the rudder and bowsprit were exciting milestones. From there the cockpit was rebuilt with some new deck beams, deck and bulkheads. Lots of painting also took place. Getting a coat of Kirby’s bronze green and fresh bottom paint on really felt good.

Overall, the project cost about 3x what I intended and took 2x longer than I thought it would (as they do). But we really got a ton of work done and I am so relieved at the state of the boat from a structural and safety standpoint, she certainly deserves it. Having dried out so long it took us two tries to launch the boat and some hasty caulking in the slings but within a week or so she took up and we were off doing charters with Sea Cadets. We had a wonderful remainder of the summer sailing weeklong trips in Casco Bay, a trip down to Marthas Vineyard for a music festival and the Gloucester Schooner festival all culminating in a homecoming to Boothbay Harbor. We still have a long list of projects and things are ongoing through the winter of 2022 with the cover on. At least for a few years the haul outs and workload will be much more manageable. The next major project will likely be a deck replacement but with some work on recaulking, refastening and fixing deck beams where needed I think we can get by for at least 5-10 years. New sails are also a priority. I cannot thank Carloyn, Brooke, the other shipwrights and everyone else involved for their hard work in making this project possible and keeping Tyrone alive.